For new investors, organic fertilizer business will be more profitable in the near future. That is because:

1. multi benefits of organic fertilizer when compared with compound fertilizer.

2. with the development of organic farming, there will be an increasing demand on organic fertilizer. Therefore, this article introduce organic fertilizer production technology and related equipment. Just for your reference!

Benefits of Organic Fertilizers

Different types of fertilizers, such as chemical fertilizers, organic fertilizers, and natural fertilizers are available on the market. The type of fertilizer you use has a large impact on the quality of your product. Farmers all over the world use chemical fertilizers, but many are now shifting to organic fertilizers due to the apparent benefits of the latter.

Organic fertilizers are carbon-based compounds that increase the productivity and growth quality of plants. They have various benefits over chemical fertilizers, which include the following:

Non-toxic Food: Use of these organic fertilizers ensures that the food items produced are free of harmful chemicals. As a result, the end consumers who eat these organic products are less prone to diseases such as cancer, strokes, and skin disorders, as compared to those who consume food items produced using chemical fertilizers.

On-Farm Production: The majority of organic fertilizers can be prepared locally or on the farm itself. Hence, the cost of these fertilizers is much lower than the cost of chemical fertilizers.

Low Capital Investment: In addition to the on-farm production possibilities of organic fertilizers, organic fertilizers help in maintaining the soil structure and increasing its nutrient-holding capacity. Therefore, a farmer who has practiced organic farming for many years will require far less fertilizer, because his soil is already rich in essential nutrients.

Organic Fertilizer Processing Equipment:

1. Compost Turner, Commercial Composting Equipment

Turning and Water Addition. The composting operation requires formation of long windrows by dumping successive loads of manure with a width of about 3m at the base and a depth of a little more than 1.5m. Either a tractor drawn tow behind compost turner or a self-powered windrow turner is used to mix the manure and turn it completely. Water may be added during this turning process either using a water wagon or by attaching an 8 cm hose attached to a reel with a take-up mechanism to the Self-powered compost windrow turner. The moisture content of the compost now produced averages 38% with a low of 19% and a high of 60%. The composting process is managed to maintain the higher moisture content for the first three weeks to maintain the composting process, and then allowed to drop for the last three or four weeks to dry the compost prior to granulation. Adequate moisture is essential to the composting process, and once the moisture content drops below 40%, the composting process is slowed. On the other hand, compost with more than 50% moisture does not screen well in a rotary screen, and the compost can plug the screen. Screening efficiency generally increases with lower moisture content. Furthermore, no more than 30% moisture is appropriate for pelletizing. Thus, moisture control is important to both the composting process and the screening and pelletizing operation.

Temperature Control. The compost temperatures and moistures are satisfactory for the current product formulation. The temperatures now being achieved are least 55 degrees C for more than three days. These high temperatures are essential for the complete destruction of human and animal pathogens, and all weed seeds. Producing a pathogen and weed-free product is one of the strongest selling points of the compost.

2. Organic Fertilizer Granulation Machine

Addressing the disposal of agricultural, industrial, and municipal wastes is becoming a growing problem. As experts in fertilizer granulation, Allance Fertilizer Machinery can offer solutions for taking organic wastes and turning them into reusable products in the form of fertilizers.

In addition, the fertilizers produced in our organics granulation systems are clean and safe: entirely free of the micro-organisms and pathogens found in industrial and municipal sludge. End product quality far exceeds federal requirements for Class “A” disposal standards as they apply to municipal wastewater treatment plants.

Other organic fertilizer making machine includes: Flat Die Fertilizer Pellet Mill, Disc Granulator, Roller Extrusion Granulator.

3. Organic Fertilizer Mixing System

Horizontal fertilizer mixer machine is horizontal type which is our new-generation fertilizer mixing equipment. The material can be fully mixed. To improve the mixing uniformity,the horizontal fertilizer mixer machine is designed in double shaft model for large fertilizer mixing capacity and used new rotor structure, the rotor close to the minimum gap can be adjusted to zero, effectively reducing the material residues, the fertilizer mixing plant can mix powder materials in many fields such as pharmacy, food, animal manure, organic fertilizer, health care products, dyestuff, building materials, refractory material, etc.

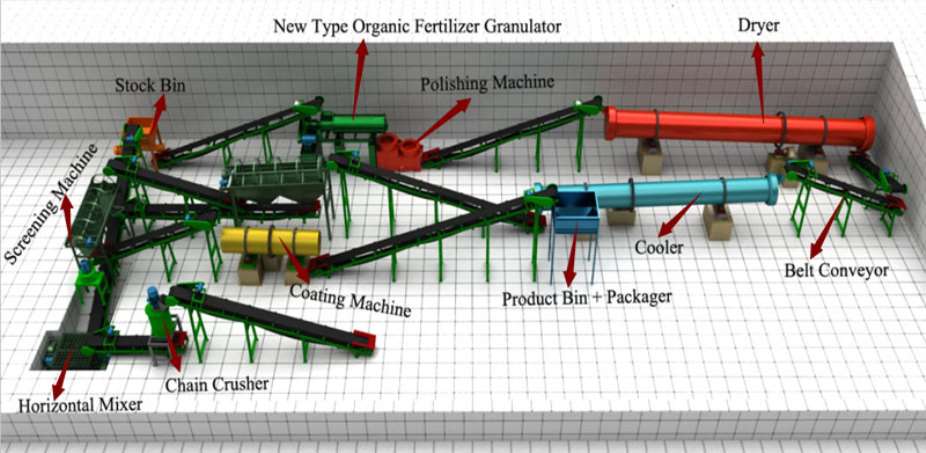

Organic Fertilizer Manufacturing Process:

http://www.fertilizer-machine.net/solution_and_market/organic-fertilizer-production-process.html

Supreme Court clears way for dual citizens to hold key public positions

Supreme Court clears way for dual citizens to hold key public positions

Be transparent, don’t suppress the truth – Prof. Opoku-Agyemang to Jean Mensa

Be transparent, don’t suppress the truth – Prof. Opoku-Agyemang to Jean Mensa

‘I won’t tell the world I was only a driver’s mate during challenges’ – Prof Jan...

‘I won’t tell the world I was only a driver’s mate during challenges’ – Prof Jan...

We’ll prosecute corrupt officials of Akufo-Addo’s govt – Prof Jane Naana

We’ll prosecute corrupt officials of Akufo-Addo’s govt – Prof Jane Naana

[Full text] Acceptance speech by Prof Jane Naana Opoku-Agyemang as 2024 NDC Runn...

[Full text] Acceptance speech by Prof Jane Naana Opoku-Agyemang as 2024 NDC Runn...

Election 2024: Don’t be complacent, we haven’t won yet – Asiedu Nketia cautions ...

Election 2024: Don’t be complacent, we haven’t won yet – Asiedu Nketia cautions ...

Election 2024: Stop fighting over positions in Mahama’s next govt – Asiedu Nketi...

Election 2024: Stop fighting over positions in Mahama’s next govt – Asiedu Nketi...

Prof Jane Naana Opoku-Agyemang will restore dignity of vice presidency – Fifi Kw...

Prof Jane Naana Opoku-Agyemang will restore dignity of vice presidency – Fifi Kw...

'Ghana beyond aid' has turned out to be 'Ghana without compass' – Naana Opoku-Ag...

'Ghana beyond aid' has turned out to be 'Ghana without compass' – Naana Opoku-Ag...

Nation builder Mahama will deliver on his promise of a 24-hour economy for the b...

Nation builder Mahama will deliver on his promise of a 24-hour economy for the b...